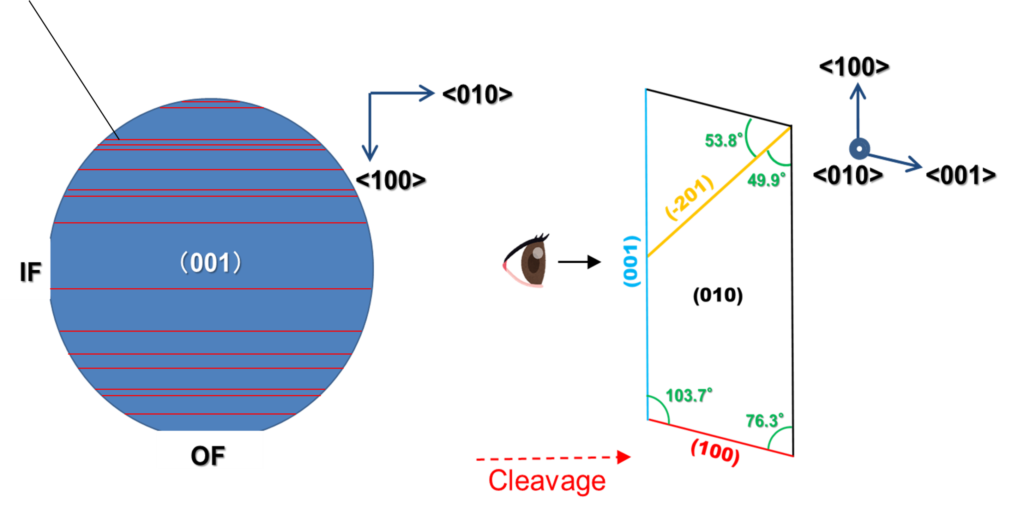

Cleavage can occur at any position parallel to the OF.

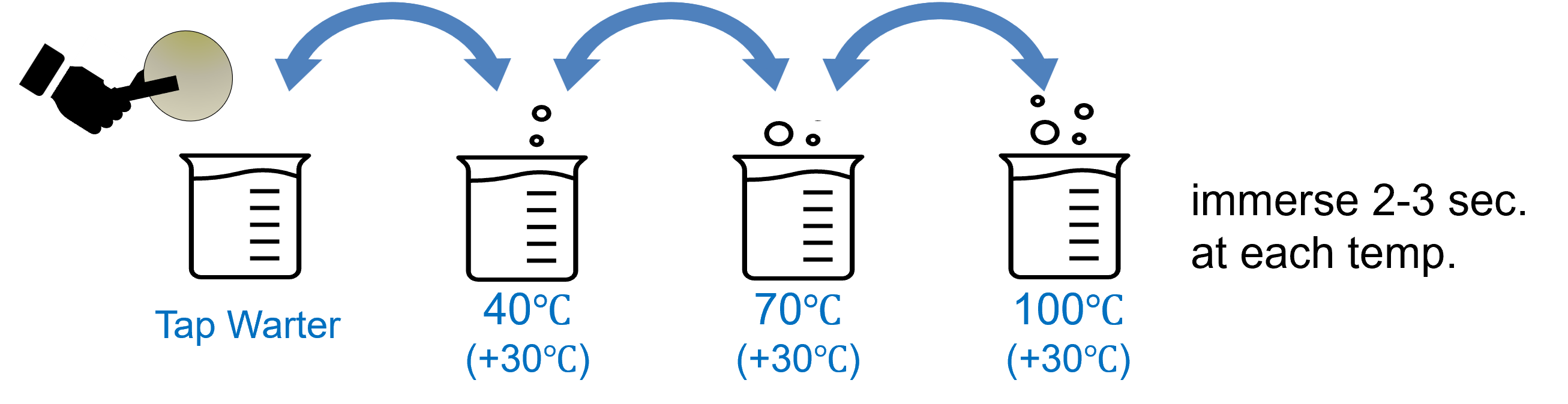

Case 1: When immersing a wafer in liquids such as water or chemical solutions.

If the water temperature is raised directly from tap water to 100 ℃, there is a risk that the wafer may crack. Therefore, the water temp must be increased in 30 ℃ increments from tap water temp to 40 ℃, 70 ℃, and finally, 100 ℃. Similarly, when lowering the temp, it must be decreased in 30 ℃ increments from 100 ℃ to 70 ℃ and then to 40 ℃. A few seconds are sufficient to immerse the wafer in water at each temp, but we leave it for several minutes just to be safe.

Case 2: When placing a wafer on a hot plate.

If you place a wafer directly on an 80 ℃ hot plate, it may crack. To avoid this, put a plate made of a material with low thermal conductivity, such as ceramics, on the hot plate, and then place the wafer on top to warm it gradually.

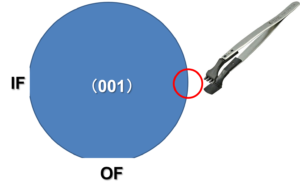

Case 3: Tweezers (wafer handling)

When holding the wafer with tweezers, grip it at the IF opposite side. This position is less affected by (100) cleavage.

Case 4: Ultrasonic cleaner

At NCT, we use equipment with high-frequency output of 144 W (60% of a 240 W system) and 192 W (60% of a 320 W system) at frequency is 37 kHz. Excessive high-frequency output may cause cracks.