Novel Crystal Technology, Inc.

Saga University

New Energy and Industrial Technology Development Organization

March 14, 2022

Third-generation gallium-oxide 100-mm epitaxial wafer

with ten times fewer killer defects

―for commercialization of 100-A-class gallium-oxide power devices―

Novel Crystal Technology, Inc., which is working on commercial development of β-Ga2O3 Schottky barrier diodes in NEDO’s “Strategic Energy Conservation Technology Innovation Program”, has developed a 3rd-generation gallium-oxide 100-mm epitaxial wafer in collaboration with Saga University. In this development, Novel Crystal Technology, Inc. and Saga University improved the epitaxial wafer manufacturing technology and reduced the number of killer defects to 1/10th that of conventional wafers. Such defects degrade the breakdown-voltage characteristics and have hindered efforts to increase the current of gallium-oxide power devices.

This development makes it possible to commercialize the use of gallium oxide in 100-A-class power devices required by trains, industrial equipment, and electric vehicles and will lead to progress in energy saving and carbon neutrality.

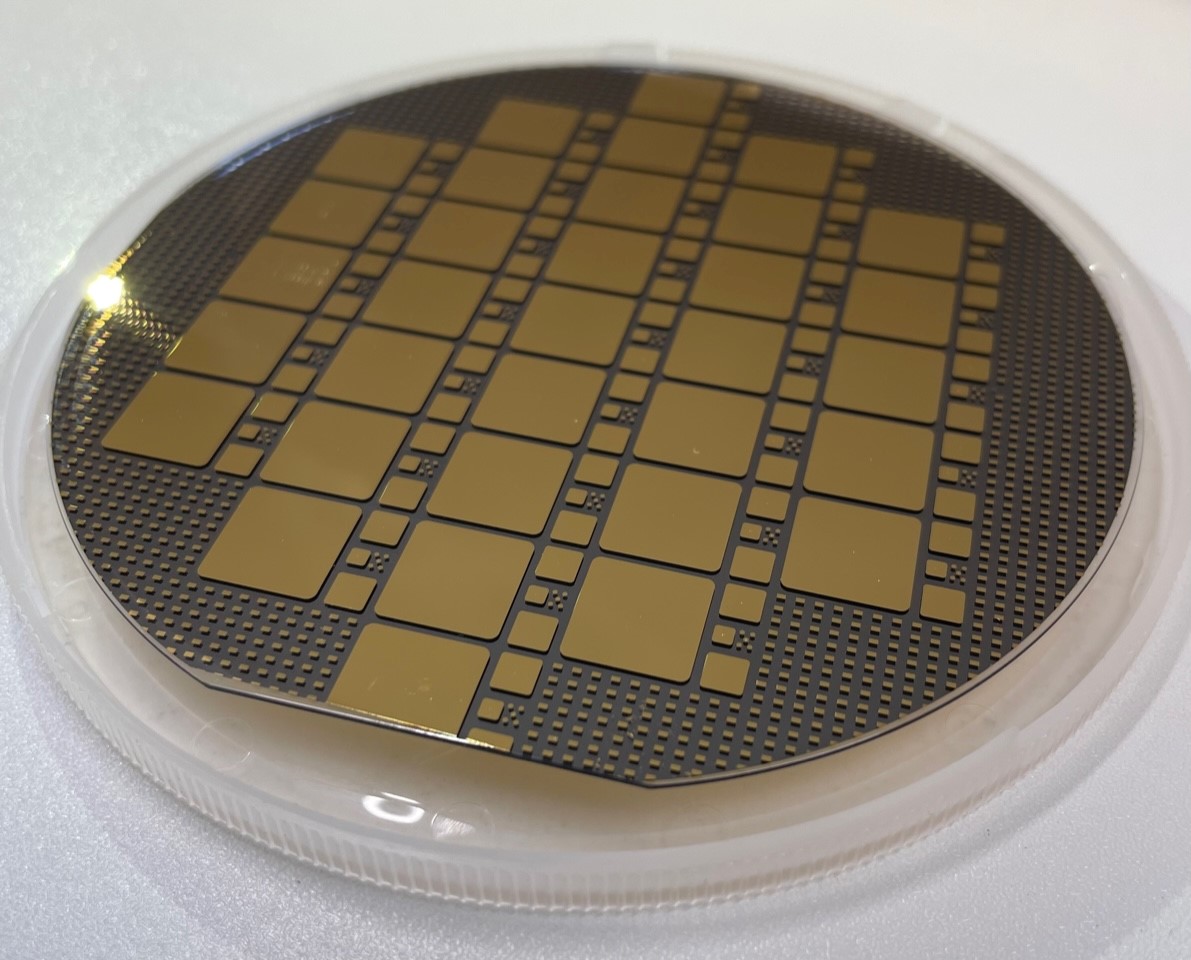

Fig. 1 Prototype Schottky barrier diode on 3rd-generation β-Ga2O3 100-mm epitaxial wafer

Fig. 1 Prototype Schottky barrier diode on 3rd-generation β-Ga2O3 100-mm epitaxial wafer

Maximum chip size is 10 mm x 10 mm.

1. Overview

Gallium oxide (β-Ga2O3) is attracting attention as a new material for low-cost power devices with low power loss. Power devices are used to control voltage and current in all types of electrical equipment from home appliances, automobiles, and trains to industrial equipment. Conventional power devices have been made from silicon, but suffer from power loss during power control. With the goal of reducing this loss, power devices made of silicon carbide (SiC) and gallium nitride (GaN) are being developed by various organizations. β-Ga2O3 is an attractive alternative to SiC and GaN because it enables the power loss to be further reduced and the power consumption of the equipment to be reduced. In addition, β-Ga2O3 can be expected to be economical because its manufacturing method is faster than that of SiC or GaN. For these reasons, research and development aimed at early commercialization of β-Ga2O3 power devices is currently underway in Japan and overseas.

Under these circumstances, Novel Crystal Technology, Inc. and Saga University have been working on commercial development of β-Ga2O3 Schottky barrier diodes in NEDO’s (New Energy and Industrial Technology Development Organization) Strategic Energy Conservation Technology Innovation Program. By improving the manufacturing technology of β-Ga2O3 epitaxial wafers1), they have managed to reduce the number of defects (killer defects2)) that degrade the breakdown voltage characteristics of the device to 1/10th that of the current generation of β-Ga2O3 100-mm epitaxial wafers. Moreover, they have recently succeeded in developing a large-scale 300-A to 500-A-class gallium-oxide Schottky barrier diode3) (Fig. 1). This new diode will make it possible to deploy 100-A-class β-Ga2O3 power devices in a wide range of markets, such as electric vehicles. The energy-saving effect of this development in the 2030s is expected to be more than 100,000 kL worth of crude oil per year, and major progress is expected toward achievement of carbon neutrality by 2050.

2. Achievements

Novel Crystal Technology, Inc. previously developed a 2nd-generation of epitaxial-deposition equipment for scaling up the size of β-Ga2O3 epitaxial wafers to 100 mm4), which are now being manufactured and sold as wafers. However, this sort of wafer has about 10 killer defects / cm2 that degrade the breakdown voltage characteristics of the device, meaning that they can’t be used to make large devices and the current is limited to about 10 A. Through its collaboration with Saga University, Novel Crystal Technology, Inc. has determined that the cause of the killer defects is a specific powder that is mainly generated during epitaxial deposition. By improving the epitaxial-deposition conditions, they have developed a third generation of β-Ga2O3 100-mm epitaxial wafer with a killer defect density of only 0.7 pieces / cm2, which is less than 1/10th that of the second generation.

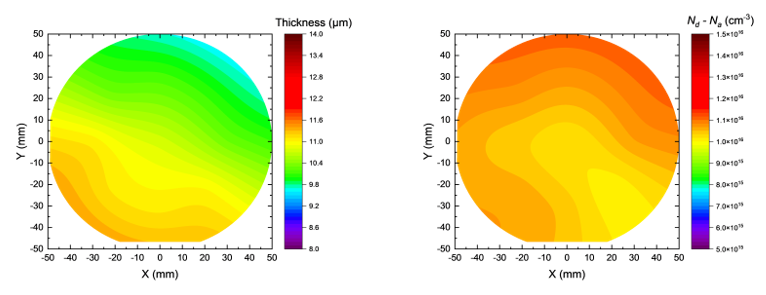

[1] Verification of in-plane distribution of film thickness and donor concentration

First, we investigated the film thickness distribution and donor concentration5) distribution of the 3rd generation β-Ga2O3 100-mm epitaxial wafer prepared under improved conditions. The results are shown in Fig. 2. Epitaxial wafers for power devices require high uniformity of film thickness and donor concentration as well as low killer defect density. The film thickness distribution and donor concentration distribution measured at nine points on the epitaxial wafer plane were very small, about 10 μm ± 5% and 1 × 1016 cm-3 ± 7%, respectively. These levels are about 1/7th those of the 2nd-generation epitaxial wafer and present no problems for power devices.

(a) Film thickness distribution (b) Donor concentration distribution

Fig. 2 (a) Film thickness distribution and (b) donor concentration distribution of

3rd-generation β-Ga2O3 100-mm epitaxial wafer

[2] Verification of killer defect density

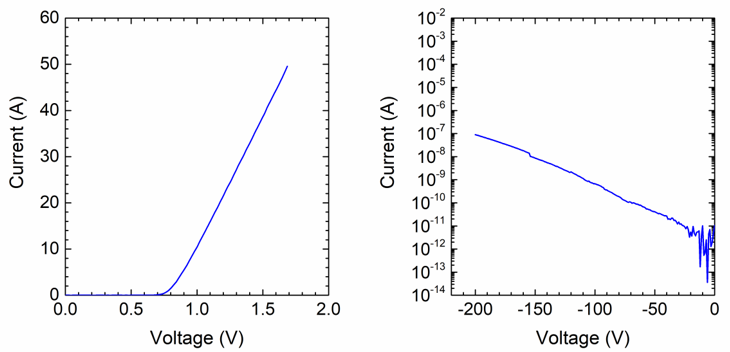

Next, we prototyped a β-Ga2O3 Schottky barrier diode (Fig. 1) on the new epitaxial wafer and evaluated its electrical characteristics and killer defect density. The largest electrode pattern on the wafer surface shown in Fig. 1 is the 10 mm × 10 mm β-Ga2O3 Schottky barrier diode used in this evaluation. Fig. 3 shows its current-voltage characteristics. Looking at the forward characteristics in Fig. 3 (a), it can be seen that the current starts to flow from about 0.8 V and rises steadily and that normal forward characteristics are obtained. The maximum current is 50 A, but this is due to the limitation of the equipment (prober) used for the measurement, and this device can flow a maximum of 300 to 500 A. Next, looking at the reverse characteristics in Fig. 3 (b), the leakage current can be suppressed to about 10-7 A even if about 200 V is applied. In the future, it is estimated that a breakdown voltage of about 600 to 1200 V can be obtained by incorporating an electrode termination structure6) into the device.

The reverse characteristic yield of the prototype diode is 51%, and the killer defect density is estimated to be about 0.7 pieces / cm2 from this value and the electrode size. This means that 100-A-class β-Ga2O3 power devices can be manufactured with a yield of about 80%.

(a) Forward characteristics (b) Reverse characteristics

(a) Forward characteristics (b) Reverse characteristics

Fig. 3 Current-voltage characteristics of (a) forward direction and

(b) reverse direction of Schottky barrier diode

3. Future plans

Novel Crystal Technology, Inc. will launch a new 3rd-generation β-Ga2O3 100-mm epitaxial wafer production line and start selling its wafers in the near future. It will continue to work to reduce killer defects even further and increase the wafer diameter while expanding the available range of donor concentrations and film thicknesses. In NEDO’s project, Novel Crystal Technology, Inc. has already succeeded in demonstrating a β-Ga2O3 Schottky barrier diode with a trench structure7) and a small power loss of 1200-V breakdown voltage.8) It will continue to create mass-production technology for pressure-resistant trench-type Schottky barrier diodes by using the products it will develop in the future.

NEDO aims to realize sustainable energy conservation that is compatible with economic growth. As described in its “Energy Conservation Technology Strategy”, development efforts such as this one will lead to commercialization of technologies will have significant energy-saving effects in the 2030s in the energy, industry, consumer, and transportation sectors.

[Notes]

1 Epitaxial wafer 2 Killer defect 3 Schottky barrier diode 4 Developed an epi-deposition device that scales up a β-Ga2O3 epi wafer to 100 mm. 5 Donor concentration 6 Electrode termination structure 7 Trench structure 8 Succeeded in demonstrating a low-loss β-Ga2O3 Schottky barrier diode with a breakdown voltage of 1200 V.

A wafer in which a crystal film is formed on a single crystal substrate. The quality of the crystal film is important mainly because the crystal film has a function.

A general term for defects that cause serious characteristic defects in devices. Defects due to crystal imperfections, polishing scratches on the wafer surface, device process defects, etc., can be killer defects. It is important to reduce the density of killer defects in order to manufacture large (high current) devices with high yield.

A diode that utilizes the potential barrier created by the junction between the Schottky electrode and the semiconductor. It features low forward voltage and low switching loss.

Reference: Novel Crystal Technology News release dated June 16, 2021

“Successful development of high quality β-type gallium oxide 100 mm epitaxial wafer”

The concentration of impurity atoms added to a semiconductor that have the ability to generate electrons. Since the breakdown- voltage of the semiconductor device is determined by the donor concentration, high uniformity and controllability are required.

In off-state semiconductor devices, the electric field is most concentrated at the ends of the electrodes. The electrode termination structure is used to alleviate the electric field concentration and increase the breakdown voltage. The types of structure include field plate, guard ring, etc.

A groove structure formed on a semiconductor surface by etching technology.

Reference: NEDO News release dated December 24, 2021

“Development of the world’s first ampere-class 1200 V breakdown-voltage”

(Contact for inquiries regarding the contents of this news release)

Novel Crystal Technology, Sales Department:

Contact Person: Masui, TEL:+81-3-6222-9336

Saga University, Public relations office: TEL: +81-95-228-8153

NEDO Energy Conservation Technology Department:

Contact Person: Kitai, TEL: +81-44-520-5281